- #GRBL ARDUINO NANO PINOUT HOW TO#

- #GRBL ARDUINO NANO PINOUT DRIVER#

- #GRBL ARDUINO NANO PINOUT CODE#

- #GRBL ARDUINO NANO PINOUT FREE#

#GRBL ARDUINO NANO PINOUT CODE#

In order to test motor two, change the motor port from 2 to 1 in the following line and then upload the code again. Some movements should be observed on stepper motor one.

Ensure you choose the correct port and board in tools and then upload the code into the Arduino board. If the Arduino IDE was open close it and open it again and click on file -> examples -> Adafruit Motor Shield Library -> stepper. Then add it into your Arduino IDE library folder.

#GRBL ARDUINO NANO PINOUT DRIVER#

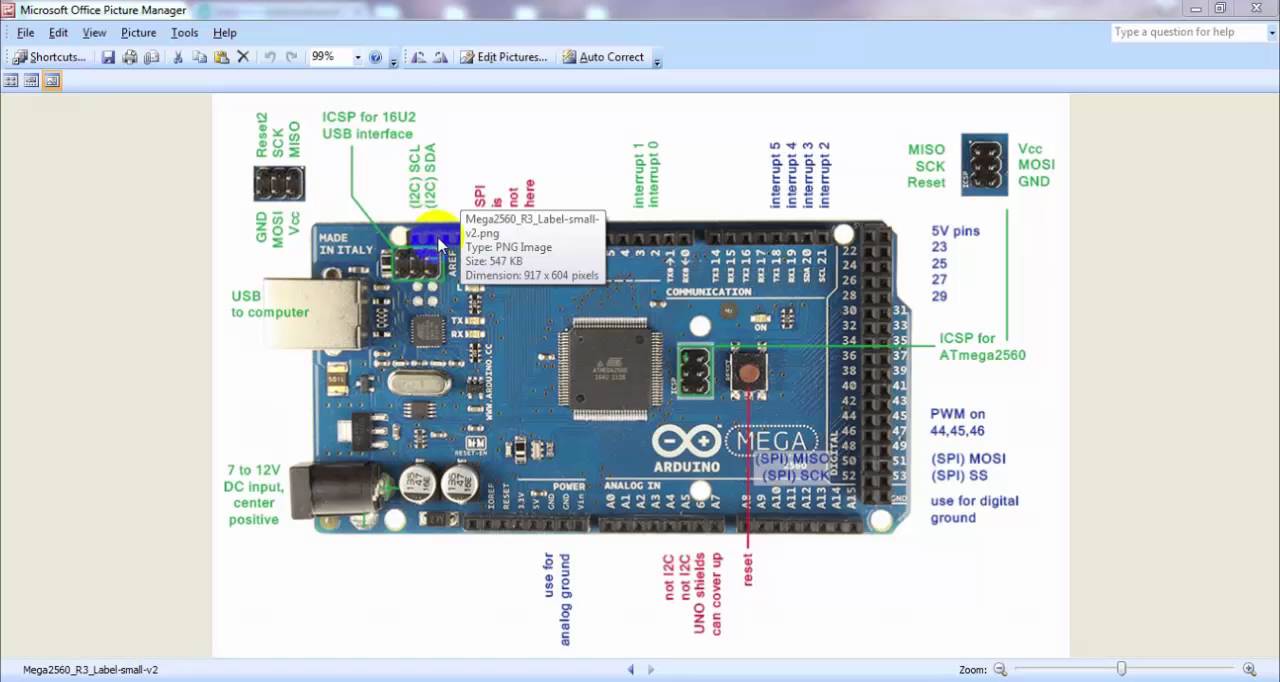

Since we are using the L293D motor driver shield, we need to download the AFmotor Library from here. The machine is now ready for testing.įirst we need to test the stepper motors and see whether they are connected correctly. Connect a 7.5V - 9V power supply to the power port of the motor driver shield. This will act as our Arduino CNC controller for our Plotter machine.Īlso attach the mini servo motor to servo1. The ground connection should be left unconnected since the motors are bipoplar type. Connect the two stepper motors as shown below. This shield can drive two stepper motors at the same time and two servo motors. Insert the L293D motor driver shield onto the Arduino UNO board. Therefore we will cut out an A5 (148mmx210mm) sized platform from the Perspex glass and then stick it onto the x-axis moving part using glue.

#GRBL ARDUINO NANO PINOUT FREE#

A good support mechanism should be constructed that will enable the free up and down movement of the pen.ĭue to the immense size of this machine, the device is capable of drawing on an A5 sized paper. This servo motor is used to move the pen up and down. Each of these parts contains a stepper motor and a belt drive mechanism usually used to move the cartridge to and fro.įor the z-axis, a mini servo motor is attached on the y-axis using glue. To make x and y axes, two printer cradles are used. The design and dimensions of my base is shown below:Īfter all the bending and cutting, I was able to produce a very firm base as shown below: In this design we will use aluminum to construct the base since it is light, simple to bend and cut and also it gives a good shiny appearance since it doesn’t rust. The main body of this device is the base which supports all the major parts of the machine together so that the machine is firm and is also portable.

#GRBL ARDUINO NANO PINOUT HOW TO#

You can chec out how to interface stepper motor with Arduino if you are new to this. The three-axis movements are provided by stepper motors, which will be ocntrolled by the Arduino board. Here we have used Arduino as the Microcontroller to build this CNC Machine. The microcontroller interprets these coordinates and then controls the positions of the motors to create the image. The z-axis is used lift and lower the pen onto the plain paper.ĭepending on the image to be drawn, the computer will generate the appropriate coordinates and send them to the microcontroller through the USB port. These x and y axis are placed 90 degrees to each other such that any point on the plain surface is defined by a given value of x and y. The x-axis and y-axis work in unison to create a 2D image on a plain paper. Check the demonstration Video at the end of this tutorial.įor a CNC plotting machine to operate, 3 axes are required (x-axis, y-axis and z-axis. It’s faster and more accurate compared to the way a human being can write or draw. It's operation is similar to the way a human hand writes. This DIY Arduino CNC Machine can draw most of the basic shapes, texts and even cartoons. You can also use this as an Arduino CNC drawing machine with little modifications. For this reason, I decided to make a simple CNC Plotter Machine based on Arduino which is by far the simplest to make. There are so a many CNC machines in the world, some of which are much technical and complex to make or even operate them properly.

CNC machines have stepper and servo motors to draw the design as per the fed program.Īfter researching on CNC machines, I decided to build my own CNC machine using locally available materials. Controller unit can be either computer or microcontroller. CNC Machines are Computerized Numerical Control Machines which are used to draw anything or design any mechanical part according to the design program fed into their controller unit.

0 kommentar(er)

0 kommentar(er)